What is Thru-Tubing Fishing and Milling?

Removal of obstructions that prevent accessing the wellbore

| Milling | Fishing |

| Scale Nipple profile Ball / flapper valve Permanent bridge plug Cement plug | Retrievable BP, packer, gauge hanger LIH string (CT, slick line or wire line) Parted coil, slick line or e-line wire Fallen object in the well |

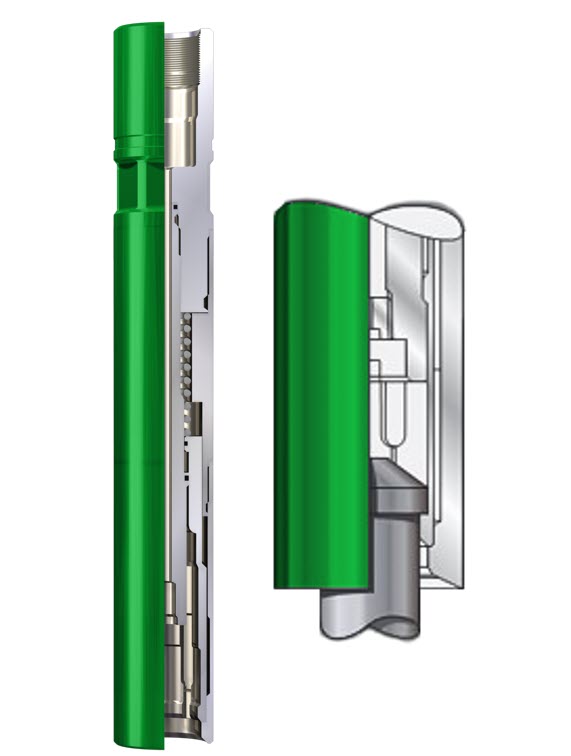

Thru-Tubing Double-Acting Accelerator

- Compression chamber stores tool energy and reduces tool length

- Large bore accommodates drop balls and equipment below the tool

- Temperature rating: 260 degC

- [500 degF]

- Seal rating: 137,000 kPa [20,000] psi

- Circulation system rating:

- 68,900 kPa [10,000 psi]

Operations:

Milling

- Mill obstruction

- Wash over / burn over

- Mill out a window

- Venturi milling and clean out

- Reaming a nipple profile

- Under reaming

- Tubing cutting

Fishing

- External fish neck

- Internal fish neck

- Slick line or wire line

- Parted coiled tubing

- Fishing loose items

- Shifting SSD

Assessment and Conditioning

- Dummy run

- High-pressure jetting cleanout

- Correlation Run

- LIB run

Document Downloads

| Title | Link |

|---|---|

| Thru-Tubing Sidetrack in North Sea Performance Bulletin | |

| TrackMaster™ Select Thru-Tubing North Sea Performance Bulletin | |

| TrackMaster Select™ Thru-Tubing (TT) in Colombia Performance Bulletin | |

| 5-1/2 inch TrackMaster Select with TT Anchor Product Sheet | |

| Red Baron Solutions Brochure | |

| 5-1/2 in. TrackMaster Select Thru-Tubing Product Sheet | |

| Red Baron Catalog | |

| Thru Tubing_N Africa_MENA Performance Bulletin | |

| Thru-Tubing Turbodrill_w Turbomill Factsheet | |

| Thru-Tubing Turbodrill Factsheet |

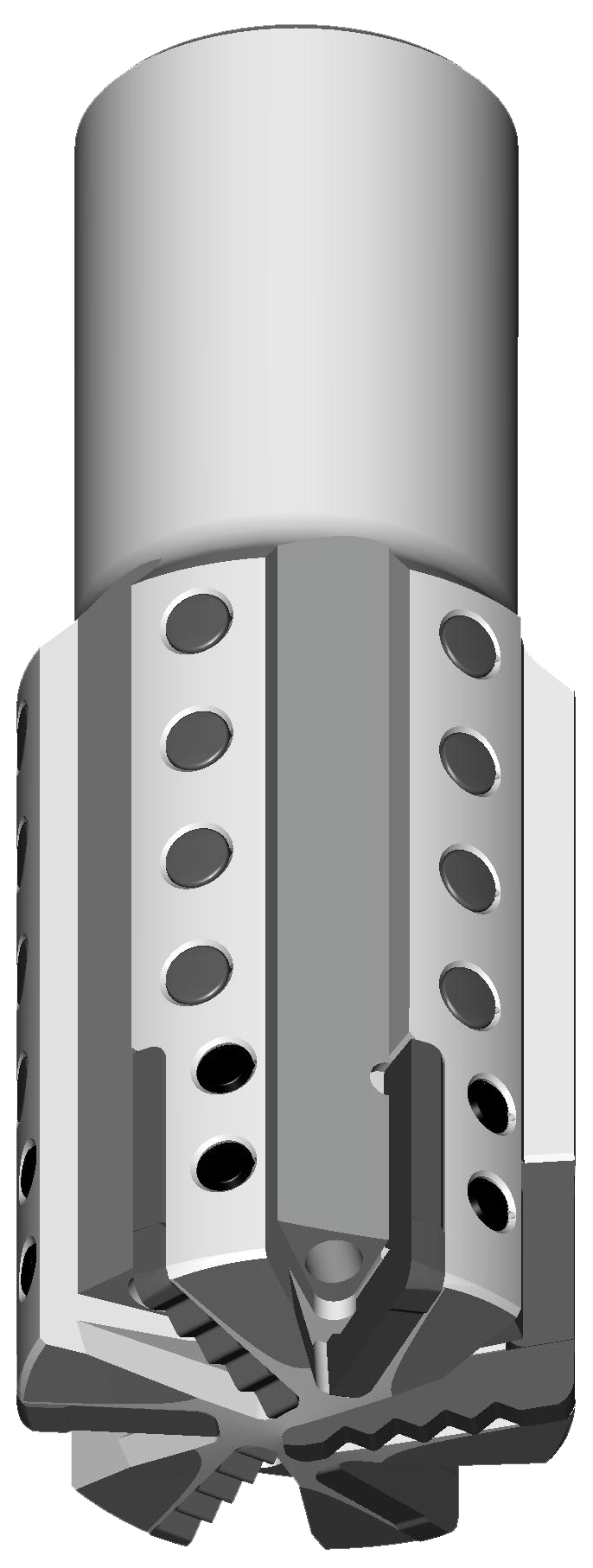

with box connection (left) and pin connection (right).

This mill is specifically designed for coiled tubing cleanouts.

Various sizes available.