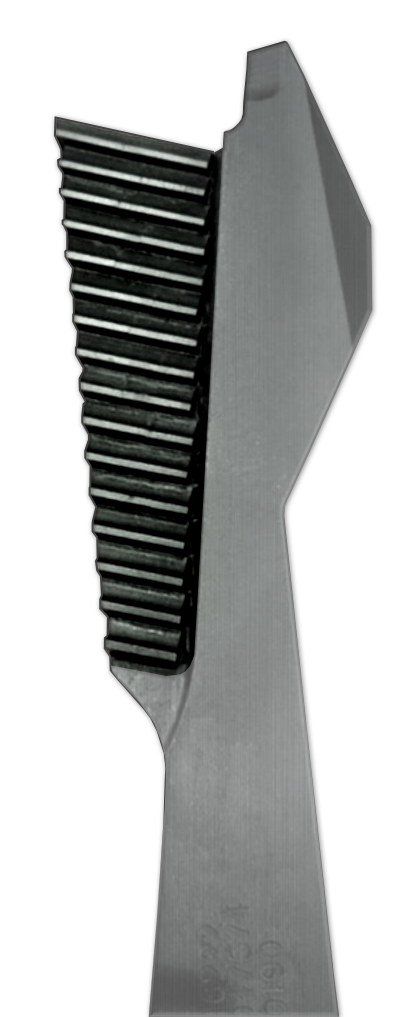

Optimized milling inserts

WIS offers optimized milling inserts technology to cover a wide range of milling and cutting applications. The inserts are engineered based on extensive lab analyses and field history to provide good cutter durability and wear resistance.

Applications

- Section milling

- ProMILL and ProMILL Duo applications

- Casing and liner milling

- Pipe cutting

- General purpose milling

Cutting Edge Technology

Intended to be used across a broad range of milling and cutting applications, from section milling and casing milling, to cut and pull systems.

The TruEdge provides an innovative, cost-saving solution for well abandonment and slot recovery applications.

TruEdge is intended to be used across a broad range of milling and cutting applications, from section milling and casing milling, to cut and pull systems. This new technology has been successfully tested with several clients in the Eastern Hemisphere, specifically in the North Sea. The test results obtained have confirmed significant rig time savings and improved the overall efficiency of the milling process.

Document Downloads

| Title | Link |

|---|---|

| Hydraulic Workover Unit Section Milling Performance Bulletin | |

| 6000 ProMILL Duo™ Operations in UAE Performance Bulletin | |

| K-Mill and TruEdge™ Record Breaking Section Milling in Algeria Performance Bulletin | |

| PullMaster* Cut & Jack System Product Sheet | |

| Well Abandonment & Slot Recovery Brochure | |

| Converge Interception Mills Product Sheet | |

| Converge Interception Mills Brochure | |

| TrackMaster Nexus™ First NAM Deployment Performance Bulletin | |

| ProMill Duo™ Complex Cap Rock Project Mid-East Performance Bulletin | |

| ProMILL Duo Technology UAE Well Abandonment Performance Bulletin | |

| First 5500 ProMILL Job in Central Asia Performance Bulletin | |

| Triple String Casing Cut Completed using TruEdge™ Technology Performance Bulletin | |

| 8200 K-Mill P&A Intervention Performance Bulletin | |

| Well Intervention Through 7in Casing Colombia Performance Bulletin | |

| K-Mill Section Milling Offshore Qatar Performance Bulletin | |

| Geothermal Solutions Brochure | |

| Red Baron Solutions Brochure | |

| Colombia ProMILL Duo & ProMILL P&A Performance Bulletin | |

| ProLatch Japan Performance Bulletin | |

| Red Baron Catalog | |

| WIS-ProMAXX Hydraulic Spear-Factsheet | |

| WIS-ProMAXX Pipe Cutter_Factsheet | |

| ProMILL Duo_N Sea_ESSA_Performance-Bulletin | |

| Pilot Mill_Brunei_APAC_Performance Bulletin | |

| ProLATCH N APAC Australia Performance Bulletin | |

| K Master_SectMill Performance Bulletin | |

| K Master 8200_ESSA_Congo Performance Bulletin | |

| ProLATCH N_APAC_W Australia Performance Bulletin | |

| Patch Installation_ESSA_ N Sea Performance Bulletin | |

| Extd ReachSpear_ESSA_UK N Sea Performance Bulletin | |

| ProMILL 9.625Casing_ESSA_Norway Performance Bulletin | |

| CutPull_APAC_Indonesia Performance Bulletin | |

| K Mill SectMill LAM_Colombia Performance Bulletin | |

| PullMaster_ESSA_N Sea Performance Bulletin | |

| ProMILL Duo_APAC_Brunei Performance Bulletin | |

| ProMILL Duo 6000_MENA_Qatar Performance Bulletin | |

| ProMILL Duo_ESSA_N Germany_Performance Bulletin | |

| TruEdge_ESSA_NorthSea Performance Bulletin | |

| WIS-DRILCO-Slot Mill_Brazil_LAM Performance Bulletin | |

| TruEdge_ESSA_Netherlands Performance Bulletin | |

| TruEdge Milling Cutting_Qatar_MENA Performance Bulletin | |

| ProLATCH Subsea PA_Japan_APAC Performance Bulletin | |

| TruEdge Milling & Cutting in Qatar – Performance Bulletin | |

| Villavicencio_Colombia Facility | |

| Villavicencio Colombia Facility – SPN | |

| TruEdge News Release RUS | |

| ProMILL Duo E Malaysia Case Study | |

| ProMILL Duo Brunei Case Study | |

| Dunlin N Sea – ProMill – Technical Article | |

| ProMill_Factsheet | |

| PullMaster Hydraulic Pulling Factsheet | |

| Section Mill Specification Sheet | |

| Casing Mill Factsheet | |

| K Master_Section Mill Factsheet | |

| ProMILL Duo Factsheet | |

| CutMaster X3_PipeCutter Factsheet | |

| Hydraulic Pipe Cutter Factsheet | |

| ProMILL Underreamer Factsheet | |

| WIS ProMILL Duo News Release PRG | |

| WIS ProMill Duo News Release SPN | |

| TruEdge News Release | |

| TruEdge News Release PRG | |

| TruEdge News Release SPN | |

| Well Abandonment Brochure |

Cutting Structures

Benefits

- Millmaster (P5) – standard grade offering for all milling applications

- WavEdge™ – high-quality inserts with improved ROP

- TruEdge™ – premium grade with improved ROP, high durability, and wear resistance.