Efficient Casing Engagement, Cutting, And Recovery

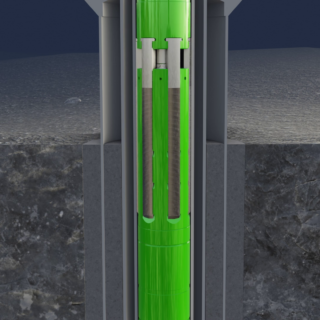

The ProMAXX-Pipe Cutter is designed to cut both single and multiple strings of pipe. It operates hydraulically, using a ball drop and pump pressure to actuate the knife arms and is designed to allow full flow through the bore of the tool to the string below.

The flow-through feature of the ProMAXX-Pipe Cutter enables other operations such as cementing, cement plug dressing, or bridge plug setting before activating the pipe cutter. By combining multiple operations in a single trip, rig time and cost is reduced significantly. Operational time savings also result in considerable emissions reduction.

One-Trip Efficient Cut and Pull System

Designed to maximize efficiency, increase reliability, and reduce environmental impacts.

As the knives of the ProMAXX-Pipe Cutter are assembled with WIS propriety TruEdge insert-only knives, multiple cuts can be made in the same trip without needing a trip to recover to the surface. The ProMAXX-Pipe Cutter chassis is mounted with a full-gauge stabilizer, which helps improve cutting efficiency by providing stabilization very close to the cutter knives.

The knife return system has been integrated into the Pipe Cutter to allow for a mechanical means of preventing unwanted knife opening when tripping in and out of the hole.

Document Downloads

| Title | Link |

|---|---|

| Hydraulic Workover Unit Section Milling Performance Bulletin | |

| 6000 ProMILL Duo™ Operations in UAE Performance Bulletin | |

| K-Mill and TruEdge™ Record Breaking Section Milling in Algeria Performance Bulletin | |

| PullMaster* Cut & Jack System Product Sheet | |

| Well Abandonment & Slot Recovery Brochure | |

| Converge Interception Mills Product Sheet | |

| TrackMaster Nexus™ First NAM Deployment Performance Bulletin | |

| First 5500 ProMILL Job in Central Asia Performance Bulletin | |

| Triple String Casing Cut Completed using TruEdge™ Technology Performance Bulletin | |

| 8200 K-Mill P&A Intervention Performance Bulletin | |

| Well Intervention Through 7in Casing Colombia Performance Bulletin | |

| K-Mill Section Milling Offshore Qatar Performance Bulletin | |

| ProLatch Japan Performance Bulletin | |

| Red Baron Catalog | |

| WIS-ProMAXX Hydraulic Spear-Factsheet | |

| WIS-ProMAXX Pipe Cutter_Factsheet | |

| ProLATCH N_APAC_Australia Performance Bulletin | |

| ProLATCH N_APAC_W Australia Performance Bulletin | |

| CutPull_APAC_Indonesia Performance Bulletin | |

| PullMaster_ESSA_N Sea Performance Bulletin | |

| ProLATCH Subsea PA_Japan_APAC Performance Bulletin | |

| PullMaster Hydraulic Pulling Factsheet | |

| CutMaster X3_PipeCutter Factsheet | |

| Well Abandonment Brochure |

Benefits

- Rapid and precise casing-cutting technology using our TruEdge cutting structure

- Enhanced operational efficiency, reducing overall project timelines

- Substantial cost savings by eliminating the need for multiple interventions

- Compatibility with various casing sizes and materials

- Improved safety standards for well abandonment operations

- Unique annular flotel design providing a clear pressure indication of cut completion

- Designed to cut a range of casing size of 9 5/8” and 13 3/8”